2023 Shanghai PROPAK is coming, Welcome to our UUPAC Booth 51E80

June 13, 2023

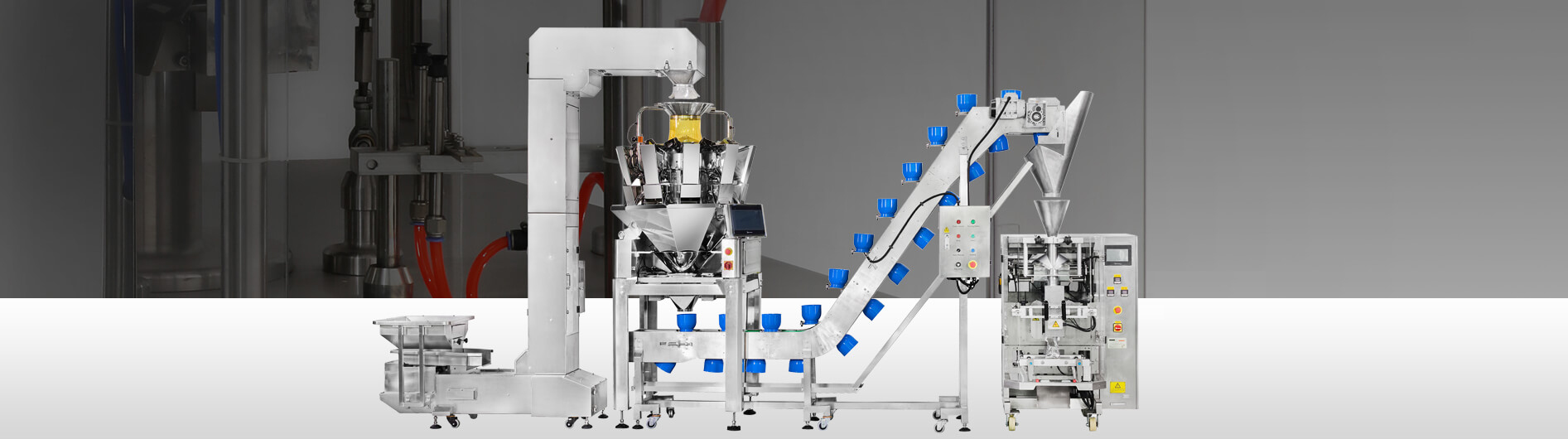

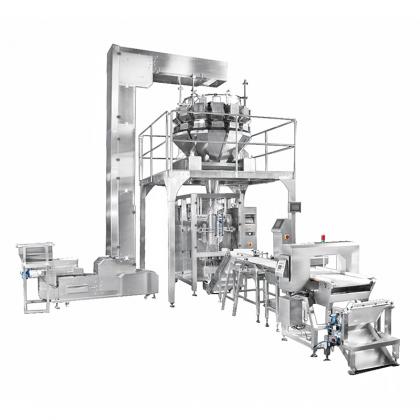

Exhibition time June 19-21, 2023 Booth Location Shanghai - National Convention and Exhibition Center UUPAC Intelligent Booth 51E80 Preview of UUPAC Intelligent Exhibition Machine The exhibited machines include high-speed weighing and packaging integrated machine, automatic mesh bag packaging machine, CW 300 cmbo metal detector and check weigher, six-level carousel sorting machine, and six-row check and reckoning machine. High-speed weighing and packaging machine High-speed weighing and packaging machine is suitable for automatic weighing and packaging of granular, short strip, lump, spherical and powder materials. Automatic Mesh Bag Packaging Machine Automatic mesh bag packaging machine is suitable for fruits and vegetables that do not need sealed packaging, such as potatoes, onions, citrus and small hardware accessories. CW 300 Combo Metal Detector and Checkweigher CW300 Combo Metal Detector and Checkweigher is widely used in that many industries of electronics, pharmaceutical, food, beverage, health products, daily chemical, light industry, agricultural and sideline products. Such as food industry seasoning, pastry, ham, instant noodles, frozen food, food additives, pigments, modifiers, preservatives, etc. Six-Level Carousel Sorting Machine Six-level carousel sorting machine is suitable for frozen products (chicken legs, chicken wings, chicken pieces), seafood (sea cucumber, abalone, small fish, shrimp), Chinese herbs, fruits, etc. (1-6 levels of weight sorting regardless of shape and material). Six Rows Checkweighing Machine Six columns checkweighing machine is widely used in pharmaceutical, food, health care products and other industries, such as granule punch, instant coffee, etc.

Read More

English

English français

français русский

русский español

español português

português العربية

العربية

IPv6 network supported

IPv6 network supported