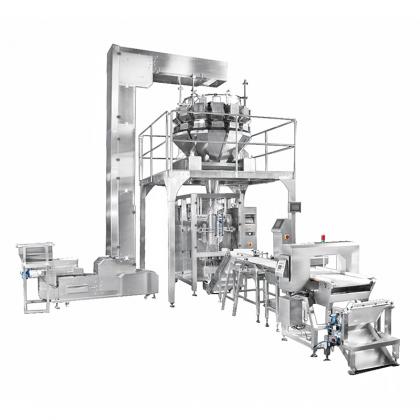

UUPAC is pleased to announce its participation in the 32nd China International Packaging Industry Exhibition (Sino-Pack 2026). Taking place from March 4 to 6, 2026, at Area B, China Import and Export Fair Complex in Guangzhou, the event will serve as a key platform for UUPAC to unveil its latest packaging technologies and solutions to industry partners and clients worldwide. At Sino-Pack 2026, UUPAC will be located at Booth 9.1B16, where the team will demonstrate cutting-edge packaging equipment and customized solutions tailored to meet the evolving needs of the food, beverage, consumer goods, and industrial sectors. Visitors can engage with UUPAC’s technical experts, explore live product demonstrations, and discuss how the company’s innovative systems can enhance production efficiency, reduce waste, and support sustainable packaging goals. Sino-Pack is recognized as one of the most influential packaging industry events in Asia, providing a vital venue for industry leaders to showcase advancements, exchange insights, and foster new partnerships. UUPAC’s participation underscores its commitment to delivering high-quality, future-ready packaging solutions while staying at the forefront of industry trends. UUPAC looks forward to engaging with industry partners and clients at the exhibition site.

Read More English

English français

français русский

русский español

español português

português العربية

العربية

IPv6 network supported

IPv6 network supported