If you're in the fresh produce business—whether running a large-scale farm, a high-volume food processing plant, or a wholesale distribution center—you know that efficiency is the heartbeat of your operation. In today's market, the right packaging does more than just hold a product; it preserves freshness, enhances shelf appeal, and directly impacts your bottom line. But as labor costs rise and delivery windows tighten, manual packaging becomes a bottleneck.

At UUPAC, we designed our Fully Automatic Mesh Bag Packing Machine to solve these exact challenges. Here is why industry leaders are choosing our solution to take their productivity to the next level.

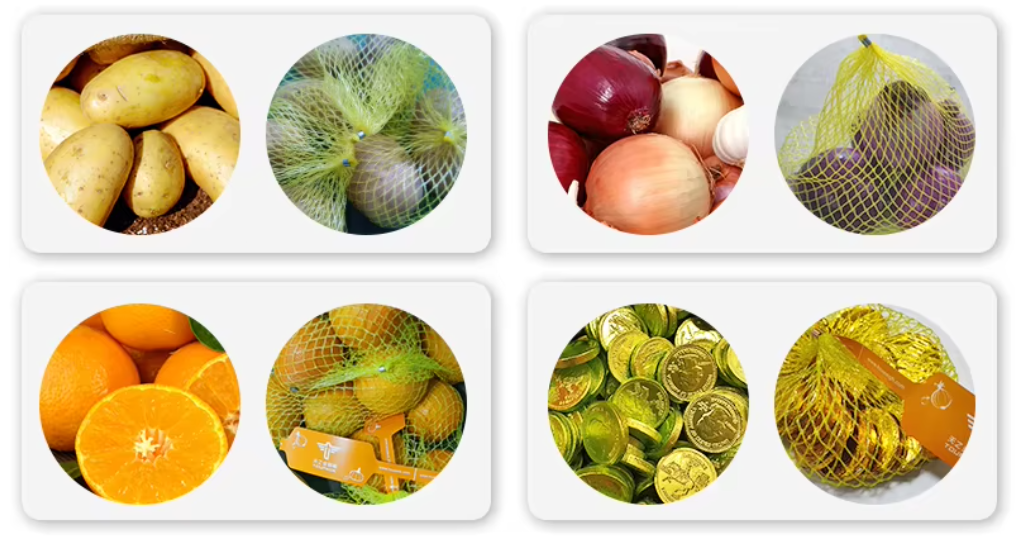

Versatile Enough for All Your Produce (One Solution, Infinite Uses)

The biggest headache in produce packaging is needing different machines for different crops. UUPAC eliminates this by offering a one-stop solution for a vast range of granular and block-shaped products.

2. High-Speed Performance That Slashes Labor Costs

Manual packaging is slow, inconsistent, and expensive. Our fully automatic system delivers a blistering speed of 25-40 bags per minute, far outpacing manual work and even most semi-automatic alternatives.

3. Food-Safe & Industrial Build for Long-Term Reliability

In food processing, durability and hygiene are non-negotiable. Our machines are built to withstand the rigors of farm and factory life:

4. User-Friendly Touch-Screen Operation

Complex machinery shouldn't be difficult to run. We've integrated world-class electronics, including an LS inverter and Schneider PLC, into a user-friendly touch-screen interface.

Quick Adjustments: Changing bag sizes, weighing parameters, or packing ties is as simple as a few taps on the screen. This ease of use ensures your production never stops, even during peak harvest seasons.

5. Precise Positioning for Professional "Shelf Appeal"

In a competitive retail environment, presentation is everything. A neat, standardized package builds brand trust. Our machine utilizes a sophisticated system of dual positioning gears and proximity switches.

Every bag is cinched and clipped with precision, ensuring consistent sizing and a professional look that stands out on grocery store shelves or at farmers' markets. Standardized packaging isn't just about aesthetics—it's about building your brand's credibility.

6. Technical Specifications

| Min.Weighing Capacity | 0.5kg |

| Max.Weighing Capacity | 5kg |

| Workable Circumference of Mesh Bag | 380/ 400mm |

| Max. Length of Mesh | 200m |

| Packing Speed | 25-40 bag/minute |

| Gross Weight | 450KG |

| Packing Dimension | 1830*1128*1849mm |

| Operational Configurations | Labelling Function |

Ready to Transform Your Packaging Process?

At UUPAC, we don't just sell equipment; we provide the technology to help your business grow. Our Fully Automatic Mesh Bag Packing Machine is the perfect investment for those who refuse to compromise on speed, safety, or quality. Do you have specific requirements for packing weight or bag sizes? We offer customized solutions tailored to your unique needs.

Contact Our Team Today to get a free quote, request a detailed demo video, or speak with an expert about optimizing your production line.

Your produce deserves the best packaging—and your business deserves UUPAC.