As Asia's premier processing and packaging exhibition, ProPak China 2025 will gather 2,500+ global exhibitors and 50,000+ industry professionals to explore cutting-edge technologies reshaping manufacturing efficiency and sustainability.

From June 24 to 26, 2025, Anhui UUPAC Intelligent Equipment Co., Ltd. will exhibit at Booth 61E50 of the 30th International Processing & Packaging Exhibition (ProPak China 2025), held at the National Exhibition and Convention Center (NECC) in Shanghai. We invite domestic and international customers to visit our booth to discover our latest intelligent equipment and integrated solutions.

Exhibition Machinery Preview

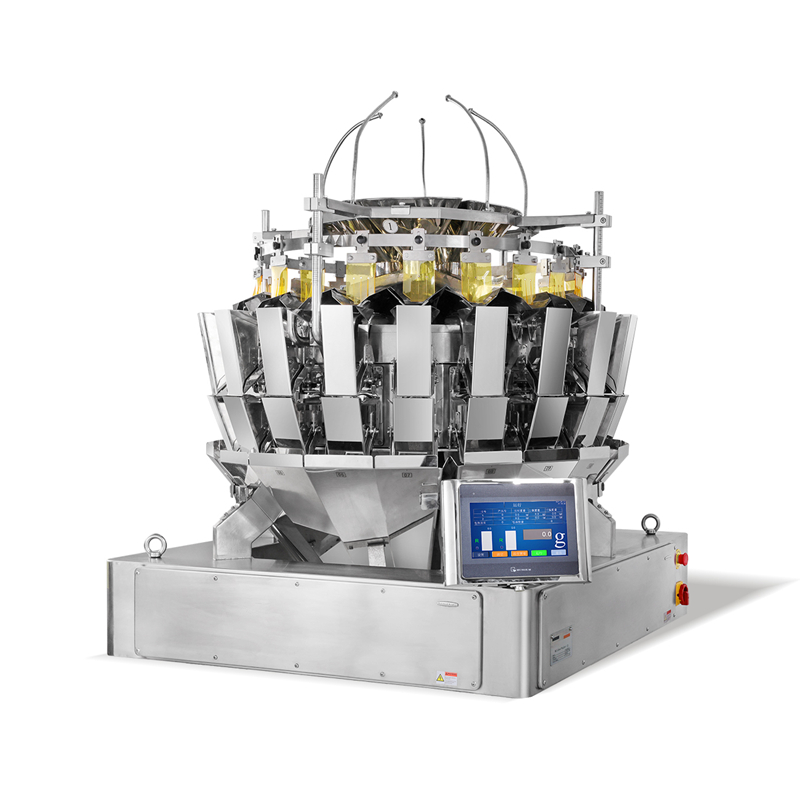

1.High Speed Multihead Weigher

It is suitable for the quantitative weighing of candy, pistachios, peanuts, nuts, almonds, melon seeds, raisins and other snack foods, as well as various granular and round materials such as plastic granules.

2. Standard Multihead Weigher

It is applied to the weighing of granular, blocky, and flaky materials in the food, pharmaceutical, hardware, chemical, and plastic industries, and is suitable for the weighing of various small granular and small-dose products, such as traditional Chinese medicine decoction pieces, pistachios, candies, coffee beans, chocolate beans, etc.

3.14 Head Weigher

It is suitable for small-measurement and high-precision quantitative weighing of small granular materials such as traditional Chinese medicine decoction pieces, tea, seeds, chicken essence, chocolate, etc.

1.X-ray Inspection System

It adopts X-ray imaging technology to detect internal defects in packaged products, bulk products and solid objects, with detectable foreign matters including metal, bone, glass, ceramic, stone, PVC, rubber, etc.

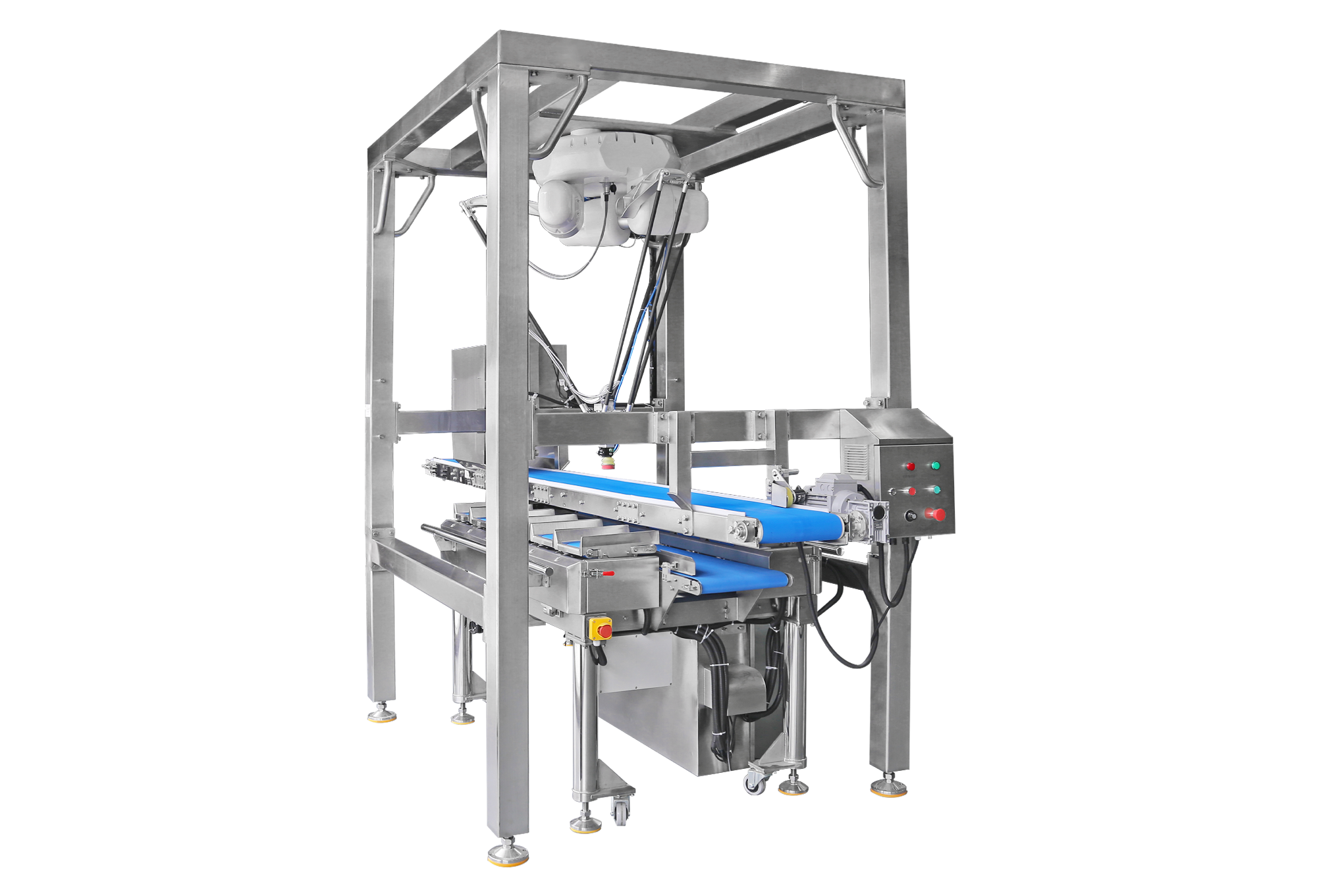

2.Delta Robot Automatic Loading & Weighing System

It is suitable for materials of different specifications, applicable to high-speed and high-precision production operations in manufacturing, food processing, pharmaceutical and other industries, capable of completing or assembling, handling, inspecting, sorting in narrow spaces, and meeting the needs of repetitive movements in 3D space.

1.520 Vertical Filling Forming Sealing Packing Machine

It is equipped with continuous film pulling, moving flying cutting and sealing functions. The longitudinal sealing adopts continuous loop belt heat sealing with preheating function, which ensures sealing quality and saves packaging film; The vacuum film pulling device ensures uniform bag length, and the automatic edge correction function makes the longitudinal seal flat, thus improving the product qualification rate.

2. Multi-Column Package Checkweighing System

It is widely applied in pharmaceutical, food, health products, daily chemical and other industries, such as granular granules, powders, liquids, etc. It can realize multiple functions including multi-row printing of tubular film rolls, slitting and bag making, material filling, sealing, weight detection, defective product rejection, collection, product height lifting, and sorting and arranging of multi-row products.

3. Fully-automatic Net Bag Packing Machine

It is suitable for net bag packaging of potatoes, onions, citrus fruits, tomatoes and other types of vegetables, fruits or other solid materials; it can be combined with conveying elevators, multi-head scales, material arranging trays and other equipment to form a complete production line.

4. Vision-Guided Robotic Case Packing Line

It can load small granular and powdery bagged materials such as chicken essence, milk powder, coffee, seeds, and dried fruits into cartons and stack them neatly.

Retractable Feeder

It is mainly used for temporary storage and conveying of granular materials such as puffed food, grain, plastic pellets, and dried fruits.