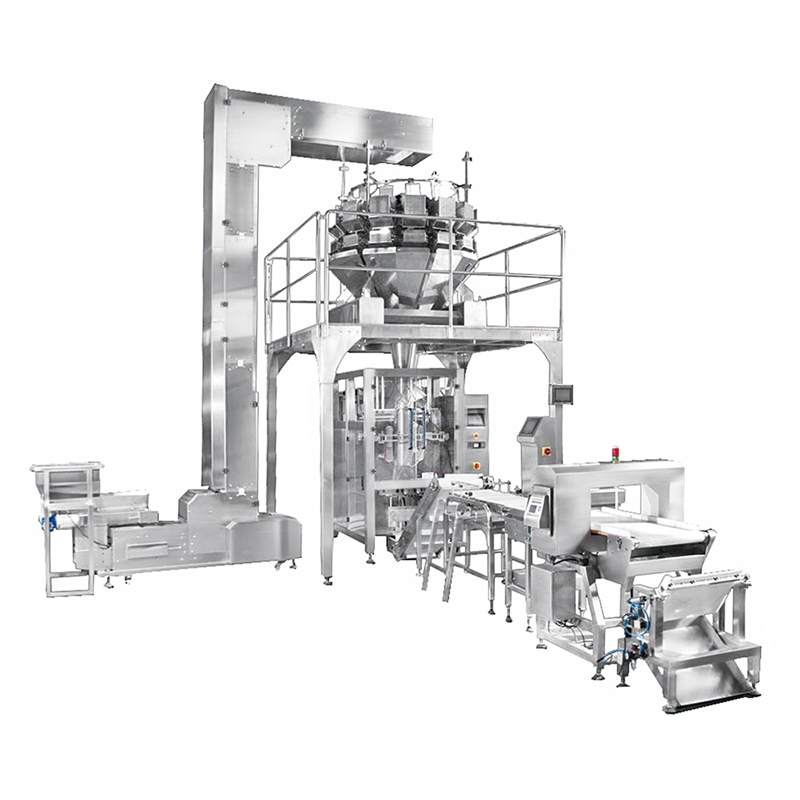

In modern production lines, accurate weighing, efficient packing, and precise detecting are essential components. Any inaccuracies or inefficiencies in these areas can lead to increased costs, product quality issues, and loss of customer satisfaction. Hence, UUPAC is proud to present our Typical Weighing, Packing and Detecting System, a revolutionary solution designed to optimize production processes.

7 Key Components of Our Weighing, Packing and Detecting System

1. Bucket Elevator: It can smoothly lift materials to an appropriate height, ensuring a continuous supply of materials .

2. Multihead Weigher: Using advanced technology, it can weigh products of different weights with high precision in a short time, meeting diverse weighing requirements.

3. Supporting Platform: The sturdy supporting platform ensures the stability of the system structure, reducing weighing errors caused by vibration and ensuring the accuracy of operations.

4. Vertical Packing Machine: It is capable of quickly packaging products in various forms, such as bags, boxes or other containers, handling them efficiently and greatly improving packaging efficiency.

5. Finished Product Conveyor: It is responsible for smoothly conveying the packaged finished products, avoiding damage to the products during transportation and ensuring the smooth flow of the production process.

6. Check Weigher: It accurately detects the weight of the packaged products and promptly screens out products that do not meet the weight standards, ensuring the weight consistency of the shipped products.

7. Metal Detector: It can sensitively detect metal foreign matters in products, guaranteeing product quality and consumer safety.

Why Choose UUPAC's Weighing, Packing and Detecting System?

1. Intelligent Automated Control

The system coordinates product feeding via fully automated mechanisms, cutting labor costs by 40% and energy consumption by 25% compared to traditional setups.

2. Precision-Engineered Work Platform

Reasonable design and soild structure of working platform to ensure the weighing accuracy is not affected.

3. Versatile & Stable Operation

Simple and scientific design of the complete line with stable running and large weighing range and high weighing accuracy features.

4. Cross-Industry Adaptability

Suitable for snack foods, puffed goods, hardware, plastics, and rubber, the system features hygienic stainless steel for food sectors and anti-static modules for industrial use.

Three Core Benefits of Our Weighing-Packing-Detecting System

1. Cost-saving

By minimizing measurement errors, reducing packaging waste, and decreasing the need for manual inspection, our system helps customers save significant costs. Over time, these savings can have a substantial impact on the bottom line.

2. Quality Assurance

The system's precise weighing and detecting capabilities ensure that only high - quality products are packaged and shipped. This helps customers maintain their brand reputation and meet strict quality standards imposed by regulatory bodies.

3. Increased Productivity

With faster packing speeds and automated quality control, the production line can operate at higher efficiencies.

Conclusion

The Typical Weighing, Packing and Detecting System is more than just a piece of equipment—it's a strategic investment for companies looking to enhance production efficiency, reduce costs, and ensure consistent product quality. We invite potential customers to contact us for more information, schedule a product demonstration, or discuss how our system can be tailored to your specific production needs. With our solution, you can elevate your production line to new levels of performance and competitiveness.