Boost Production Efficiency with UUPAC's Multihead Weigher

Boost Production Efficiency with UUPAC's Multihead Weigher

How UUPAC's Fully Automatic Net Bag Packing Machine Solves 3 Major Vegetable Packaging Inefficiencies

How UUPAC's Fully Automatic Net Bag Packing Machine Solves 3 Major Vegetable Packaging Inefficiencies

The Role of High Accuracy Linear Weigher in Food Industry

The Role of High Accuracy Linear Weigher in Food Industry

UUPAC Fully Automatic Intelligent Powder Weighing & Packing Machine: Streamline Your Powder Packaging Process

UUPAC Fully Automatic Intelligent Powder Weighing & Packing Machine: Streamline Your Powder Packaging Process

Food Packaging? See How UUPAC Rotary Vacuum Bag Feeding Machine Automates Your Packaging Line

Food Packaging? See How UUPAC Rotary Vacuum Bag Feeding Machine Automates Your Packaging Line

UUPAC 4-Head 0.5L High-Speed Linear Weigher: Compact, Accurate Solution for Mid-Volume Production Lines

UUPAC 4-Head 0.5L High-Speed Linear Weigher: Compact, Accurate Solution for Mid-Volume Production Lines

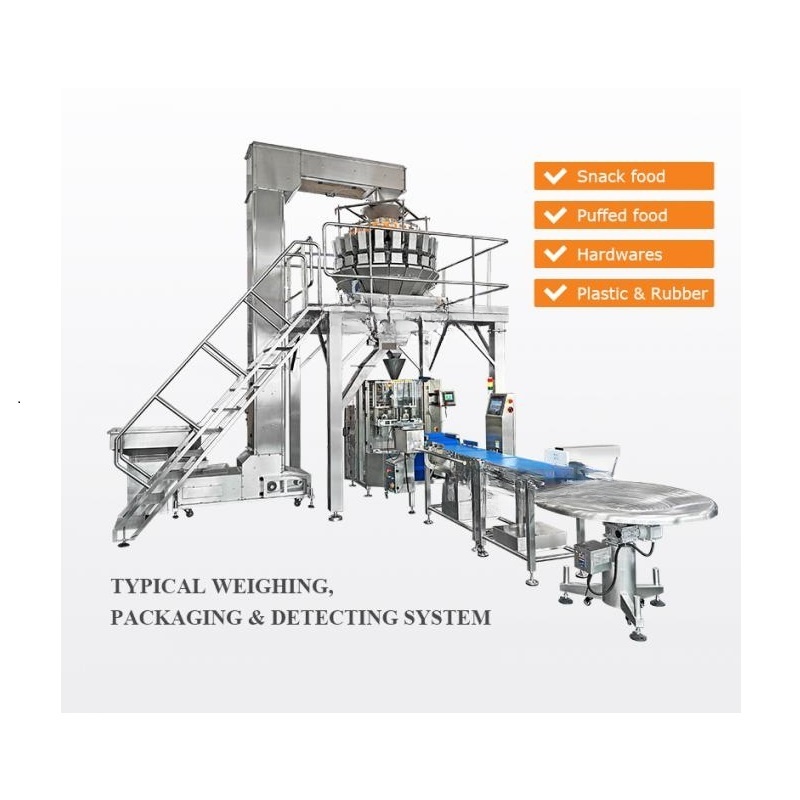

Maximize Your Output: The Comprehensive Guide to High-Speed Weighing and Packing Systems

Maximize Your Output: The Comprehensive Guide to High-Speed Weighing and Packing Systems

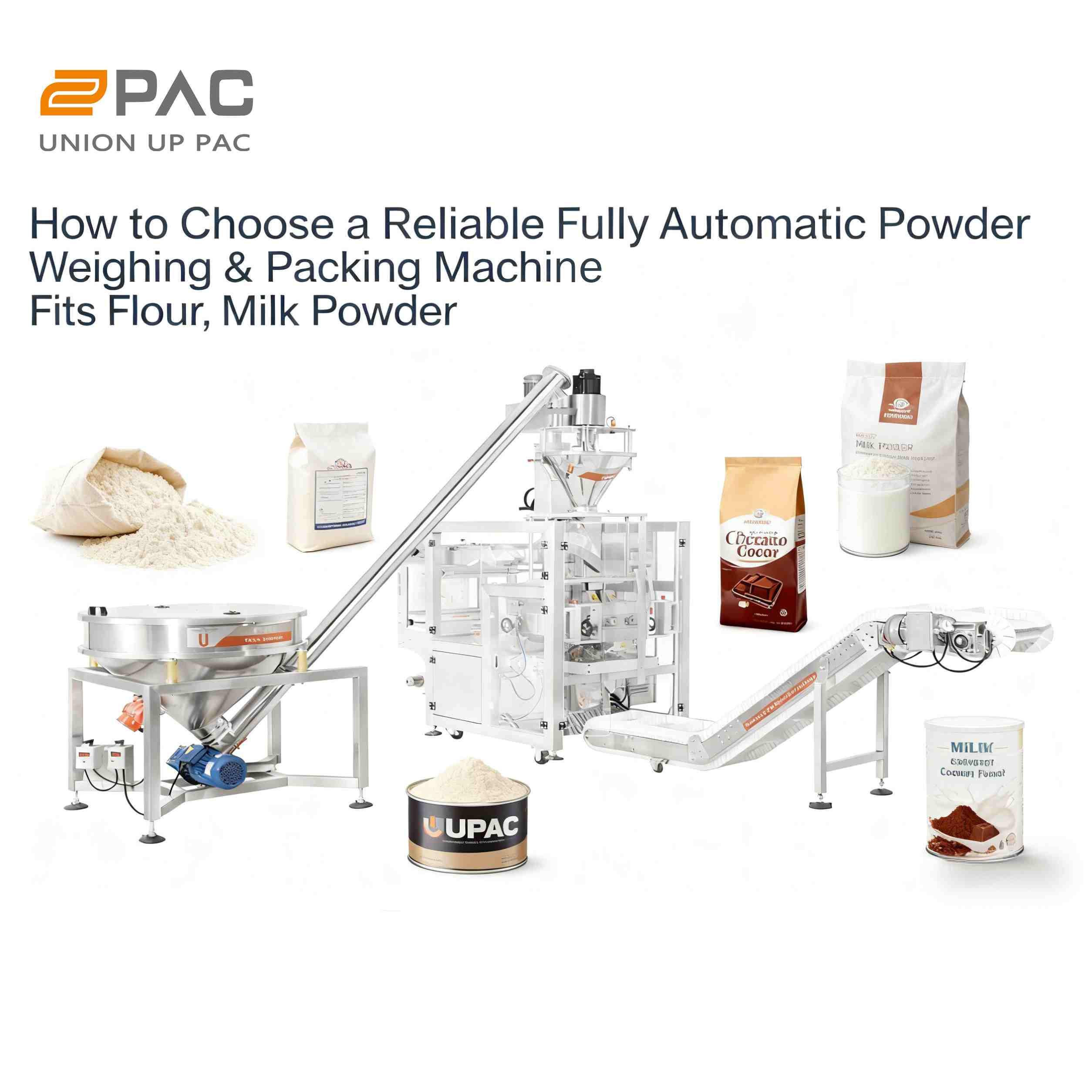

How to Choose a Reliable Fully Automatic Powder Weighing & Packing Machine? UUPAC's Solution Fits Flour, Milk Powder

How to Choose a Reliable Fully Automatic Powder Weighing & Packing Machine? UUPAC's Solution Fits Flour, Milk Powder